Fascination About Motorcycle Parts New Zealand Specialists

Table of ContentsThe Definitive Guide to Motorcycle Parts New Zealand SpecialistsAn Unbiased View of Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsThe Greatest Guide To Motorcycle Parts New Zealand SpecialistsThe Greatest Guide To Motorcycle Parts New Zealand SpecialistsThe Definitive Guide to Motorcycle Parts New Zealand SpecialistsOur Motorcycle Parts New Zealand Specialists PDFsThe Single Strategy To Use For Motorcycle Parts New Zealand Specialists

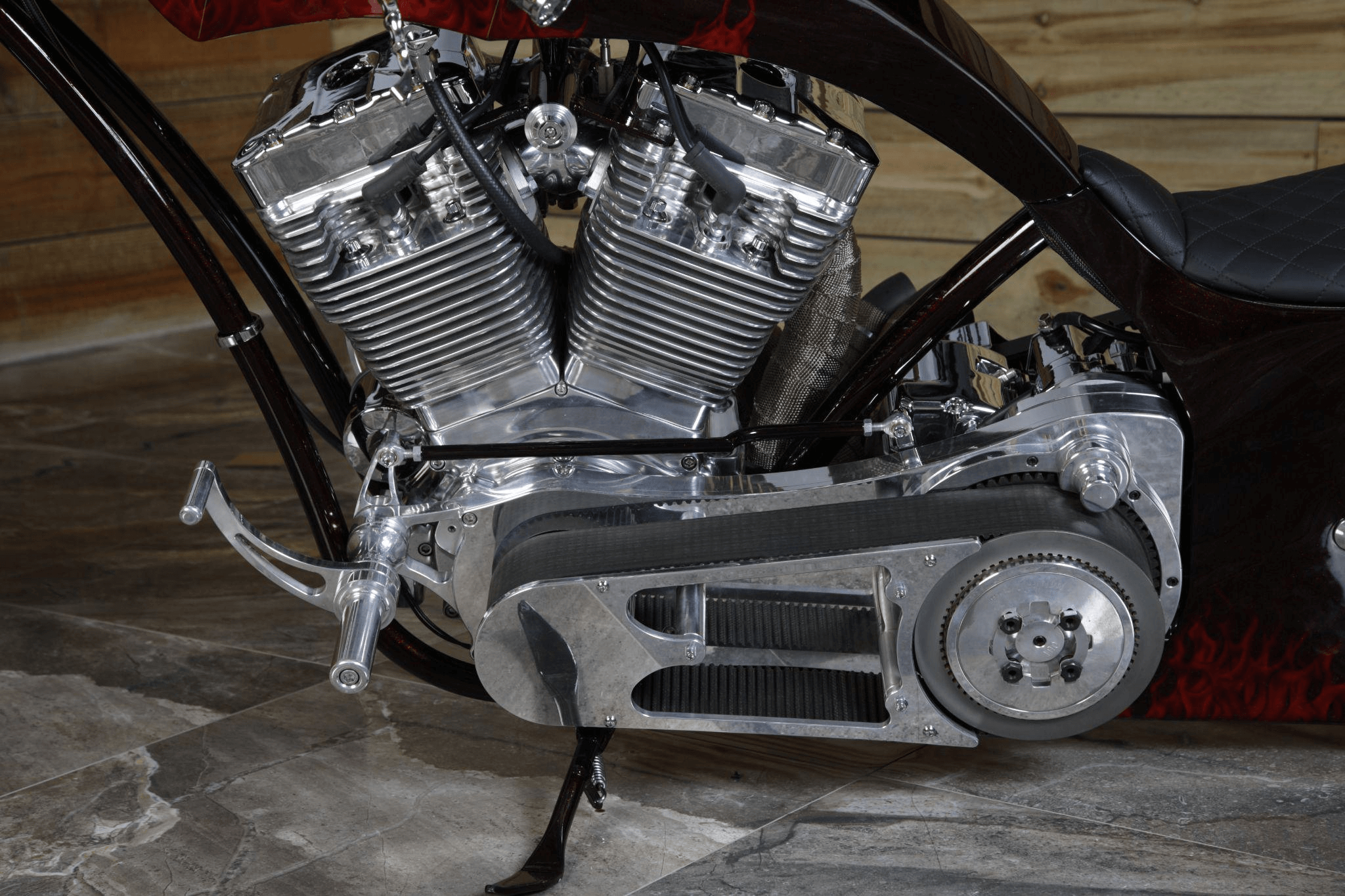

Reach out to one of our specialists today.CNC machining technology is quickly becoming the centerpiece of several manufacturing processes around the world as a straight outcome of its several benefits over various other techniques. Additionally, the markets that produce bikes have jumped on board with this fad. One of the most cutting-edge business are currently creating their engine components and wheels making use of machining methods originally created for motorcycle parts.

You might be questioning why we make use of. Currently that we have your focus allow us explain the rationale behind this modern-day growth in the motorbike manufacturing market.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

In enhancement, you have complete control over the appearance of the elements, also down to the min details. Periodically, motorcyclists might make a decision to spruce up their adventure by installing aftermarket parts or modifying the bike's remodeling.

What Does Motorcycle Parts New Zealand Specialists Do?

CNC machining might be made use of to make nearly all of a bike's steel and plastic elements. To proceed, we'll review a number of machined components for motorcycles. Unlike those on cars and trucks, wheels on motorcycles often tend to be much more evident. Consequently, the bike's appearances may be improved with the suitable customization of these wheels.

When personalizing the wheels, the disks are where the emphasis needs to be. The majority of them are constructed out of aluminum. Aluminum alloys are popular for the impressive machining abilities that they have. Milling procedures are made use of to acquire the wanted degree of wheel customization. One more element of the motorbike that might be individualized is the tires.

What Does Motorcycle Parts New Zealand Specialists Mean?

When it comes to a vehicle (or a motorbike), the most vital component is the engine. Numerous individuals allude to it as the "heart" of the automobile. On the various other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be detailed and require designs with a high degree of precision.

Usage only premium things, nonetheless, since these lights are vital for the security of motorcyclists and other drivers or individuals on the roadway, specifically at evening. Bike headlights have three major parts: the bulb, or light resource, the lens, and the housing.

Milling processes with a flawless coating would cause the lenses having a reflective top quality that is similar to that of a mirror. The cover, click site on the other hand, is not composed of fragile materials; rather, it is created out of challenging polymers that can be machined right into even more detailed patterns.

Some Of Motorcycle Parts New Zealand Specialists

Motorcycle manufacturers usually cast these elements, but just for the production of bespoke components. Machining on five axes in today's world is the methods by which any type of design form might be recognized.

The success of the procedure is contingent on the mill cutters' ability to determine refined and challenging angles accurately. Pick Runsom for your customized motorbike components! We have the capability to produce challenging and elegant parts making your motorcycle matchless. Most are crafted from aluminum or steel alloys, each of which has its uses and advantages.

Here are a couple of examples of steels frequently utilized in motorbike element machining. Light weight aluminum is the primary material used by companies specializing in creating customized motorcycle components to develop many of these components - Motorcycle Parts New Zealand Specialists.

Zinc refers to an additional metal that is extremely light in weight and has great machining high qualities as a result of its high mechanical strength. This material might be created into nearly any kind of shape and preserves its measurements well. Even mission-critical elements that need a high degree of accuracy may gain from their use.

Fascination About Motorcycle Parts New Zealand Specialists

One more steel that sees hefty use in the production of CNC-customized components is magnesium. It is amongst the lightest steels that are now obtainable and has outstanding machinability attributes and strength commensurate with its low weight. Among the downsides of magnesium is that its dust may quickly check my site capture fire.

Their most typical usage in producing different motorcycle parts is fasteners, such as screws and screws. Their low vulnerability to oxidation and corrosion makes them optimal for this use.

Examine This Report on Motorcycle Parts New Zealand Specialists

It appears that CNC turning and grating are the fundamental processes. In enhancement, it needs keeping bars of material, most usually plastic or metal, in placement and after that turning a reducing tool to get go to this site rid of sections of the product as the product is transformed.

These approaches are just as important and produce components with high accuracy and constant top quality. The processes assist improve the general top quality of the machined bike elements.

5 Easy Facts About Motorcycle Parts New Zealand Specialists Explained